|

|

TriContient

Syringe Pump Control

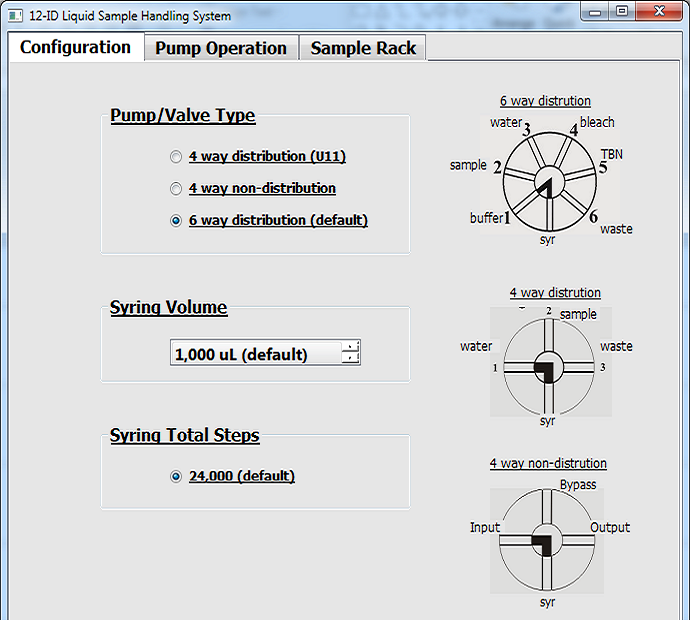

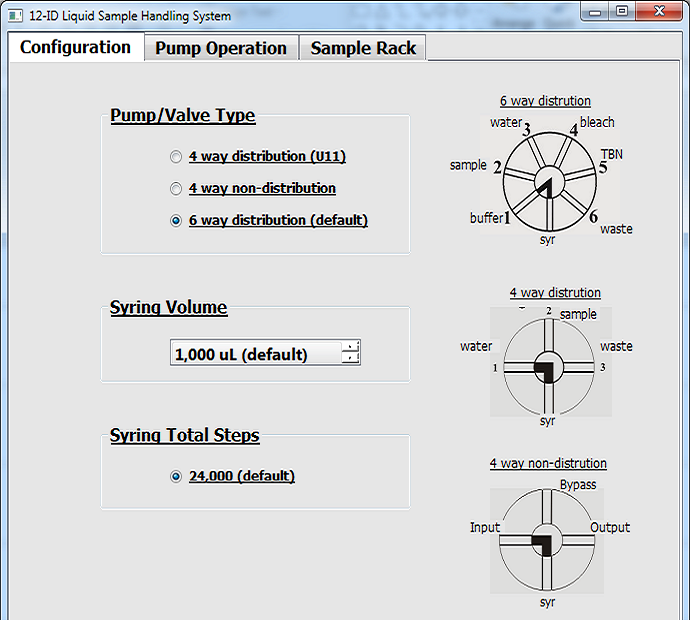

A. Valves:

|

Valves:

6

Way valves connecting to:

#1:

buffer

#2:

flow cell

#3:

water

#4:

bleach

#5:

TBA

#6: waste

|

|

B.

Functions:

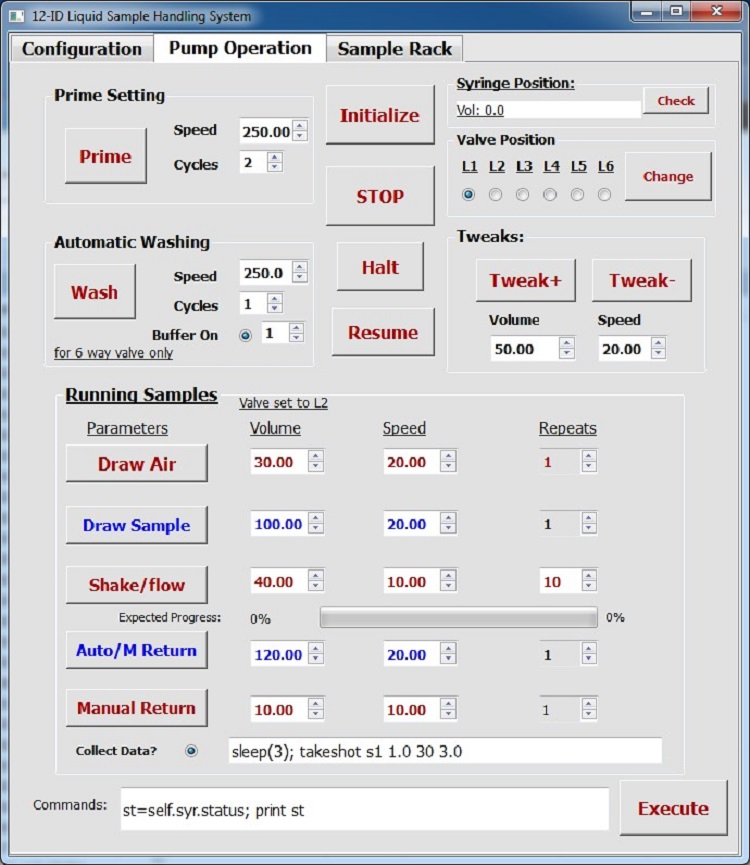

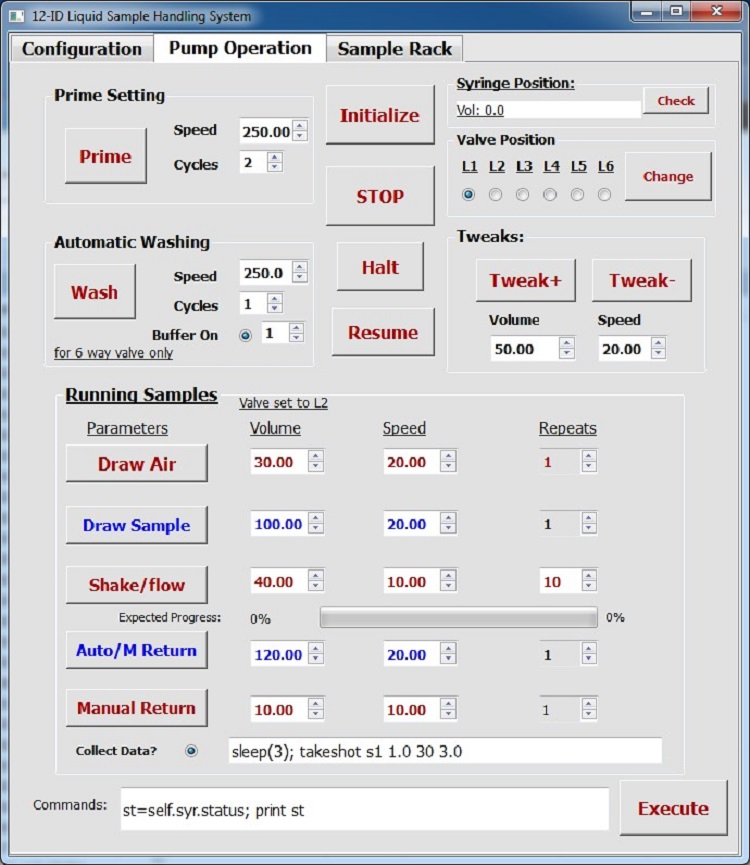

Prime:

Flow direction: flow cell --> valve #2 --> syringe

--> waste

Valve position: #2 & #6,

automatically chosen by program

Often use for manually washing the flow cell.

Wash:

Wash the flow cell automatically with water, bleach, buffer, etc.

Flow direction: washing bottles --> syringe --> valve #2

--> flow cell --> funnel --> waste

Valve position: automatically

chosen by program

The

automatic washing includes sequential washings: TWO times washing with

WATER, TWO times with BLEACH, THREE times with WATER, and optional

washing with your buffer.

!!! When you do

washing, make sure the tubing pointing to the waste funnel !!!

|

|

Running Samples:

In this section, one can load sample and run it. The sample will be

pushed back and forth to reduce possible radiation damages.

Note: the pump speed and volume to operate can be set.

The net volume at the end of this section should be ZERO,

otherwise, air will be accumulated or pump will not be able to run

correctly.

Valve position: automatically chosen by

program

Draw Air:

To obtain smooth flow, the tubing should be filled with liquid. Draw

air gap to separate the sample/buffer to the rest liquid in the

tubing/flow cell.

Draw

Sample:

Load sample. No air bubbles are allowed to be sucked in at this step.

Shake/flow:

Push the sample back and forth. If the radio button "Collect

Data?" is selected, scattering data will be collected while

the sample flows. Set proper Speed and Repeats

values to cover the data collect period.

"Collect Data?" box: data collection

command entered here. For example, "sleep(3);

takeshot s1 1.0 30 3.0" means: data collection will

occur at 3 seconds after the sample begins to flow; the data file name

will be "s1"; x-ray exposure time will be 1.0 second; 30 frames of

images will be collected; data will be collected every 3.0 seconds

(i.e. 1.0 second with x-ray on sample and 2.0 seconds without x-ray on

sample for this case).

Auto/M Return:

Supposedly, pump will automatically return the sample to the sample

tube in this step. Occasionally, pump may miss this command and does

not return sample. Check if the samples is returned, if not, push the

button and manually return the sample.

Manual Return:

This step is intentionally to bring pump to zero position after

removing sample tube. After pump moves to zero position, it is ready to

run the next sample.

Check Syringe Position

The status box reports the syringe position(volume) and valve position.

the Check button can be used to check/update the

syringe and valve positions.

Syringe and Valve Operations

- changing valve position, select the desired

valve (L1-6) and push the Change

button.

- move syringe by Tweak+ or Tweak-

button with desired volume and speed. Tweak+ will

load liquid and Tweak- will unload liquid.

Other Functions

Initialize button will bring syringe to

default position, i.e., zero volume and valve #6.

Automatic Sample Changer (AutoSampler)

C. Known problems and

trouble-shootings

Problem: All operation commands

are sending through network, therefore, commands may be lost.

Answer:

Always check the status and see if the pump acts as expected. If not,

repeat the action.

Problem:

While Running Samples, the Auto/M Return function supposedly

automatically return sample, however, occasionally, this command may be

ignored.

Answer:

Check the sample tube or the volume if the sample is returned. If not,

click Auto/M Return button to return sample.

Problem:

Pump program is frozen.

Answer:

Find the terminal where the program was started, press keys "Ctrl" +

"z" to terminate the program. In folder

/home/beams/S12IDB/python_codes/triContinent, run "python

triCont6WPyQt.py" to restart the program.

|

|